Tin Catalyst Alternatives for Polyurethane Coatings

September 15, 2024 | Blog

Choosing the right catalyst for your polyurethane formulations is crucial for achieving optimal performance and compliance with regulatory standards. Due to regulatory concerns and potential health effects of the tin, many formulators for coatings, adhesives, and sealants are now considering tin-free catalysts.

In this blog, we’ll discuss the performance and safety benefits of replacing tin with tin-free catalysts in polyurethane systems.

Introduction to Catalysts in Polyurethane Coatings

Why are Polyurethane Coatings Used?

Polyurethane coatings are popular across a wide range of industries. These include automotive, protective and marine, wood, and construction. They offer a unique combination of durability, versatility, and performance.

The Importance of Catalysts in Polyurethane Coatings

Without metal catalysts, curing would occur at a much slower rate, slowing down the production process. Catalysts also influence the final properties of the coating. These include hardness, pot life, and resistance to corrosion or chemicals.

The right catalyst ensures that a coating achieves the desired performance characteristics. As regulations increase, a catalyst that complies with regulatory standards is also crucial.

Overview of Tin Catalysts

Why are Tin Catalysts Used?

Many formulators widely use tin catalysts in polyurethane coatings. Organotin compounds such as dibutyltin dilaurate (DBTDL) and dioctyltin dilaurate (DOTL) are renowned for their reliable and strong performance.

These tin-based catalysts are compatible with many polyols and isocyanates and provide good drying times and mechanical properties.

The Regulatory Risks of Tin Catalysts

Even though the use of tin catalysts is still very popular, there are rising concerns among coating formulators. Tin compounds can cause skin and eye irritation as well as disruptions to the endocrine system.

Several regions have imposed regulations on organotin compounds. In the European Union (EU), some organotin compounds like DOTL are listed on their Candidate List of substances of very high concern. Companies using items on this list must provide adequate safety labeling if more than 0.1% weight of an item is used.

Under REACH Annex XVII restriction 20 in the EU, more than 0.1% weight of DBTDL is also restricted in consumer products.

Regardless of tin catalysts’ performance, it’s important for formulators to think about the possible long-term risks they might bring. Formulators should consider viable substitutes that meet both performance and regulatory requirements.

The Rise of Tin-Free Catalysts

Lower Toxicity than Tin

Tin alternative catalysts can have reduced regulatory risks and provide similar or improved performance as their tin counterparts. Zinc, zirconium, and bismuth catalysts are examples of tin alternatives.

Replacing organotin with tin-free catalysts helps formulators comply with current and future tin regulations, ensuring their products meet changing standards. Organizations that are committed to sustainability may want to consider tin-free options.

Performance and Efficiency

Formulators have favored tin catalysts due to their ability to provide rapid curing times and consistent mechanical properties. These include hardness and pot life.

On the other hand, tin-free catalysts have made significant strides in dry performance, hardness, corrosion resistance, pot life, and color.

However, it is important to note that tin-free catalysts are not a 1:1 replacement to tin. Formulators must conduct tests to determine the right catalyst and dosage for coating formulations.

Making the Best Choice

Assessing Your Formulation Needs

Assessing the needs of the formulation begins by evaluating the specific performance requirements of your polyurethane coatings. Consider organotin regulations for the regions in which you sell coatings. Additionally, analyze the long-term sustainability goals of your organization, as adopting sustainable practices can enhance your brand’s reputation and compliance status.

Performance Case Studies with Borchers’ Tin-Free Catalysts

At Milliken & Company, we provide Borchers brand additive options that can help enhance sustainability in coating formulations. These include our Borchi® Kat catalyst product line as well as other tin alternatives.

Our technical experts have examined the use of Borchi Kat as well as an experimental tin-free catalyst versus DBTDL in various polyurethane coating formulations, including:

- High solids white topcoat for metal

- White topcoat for airmix and airless application

- White topcoat vehicle refinish

- White topcoat protective and marine

Our team conducted the following tests comparing tin alternatives with DBDTL:

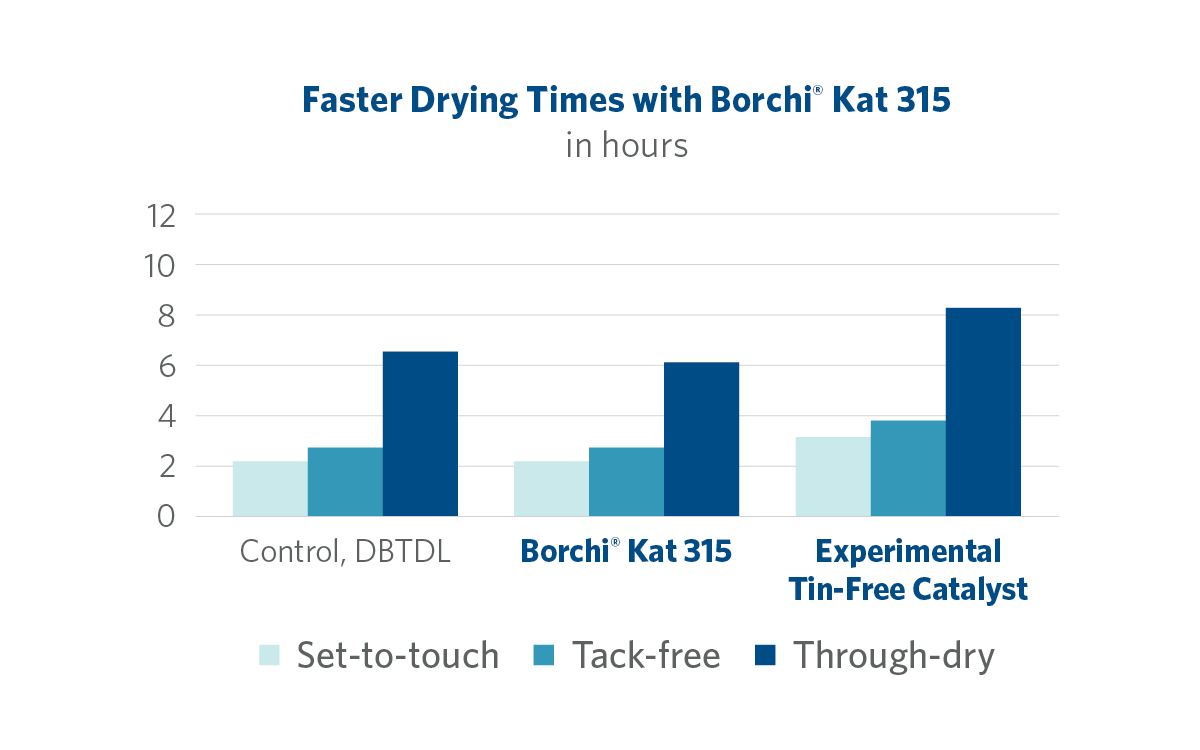

Drying Times

Fast drying times allow for an efficient production process in a number of applications. In this study, drawdowns were applied on Mylar sheets at wet film thicknesses of 100 microns. Drying times were measured with Circular Drying Recorders.

In a white topcoat for protective and marine coatings, tin-free catalysts showed good dry times compared to DBTDL. Borchi Kat 315 provided faster through dry times than DBTDL.

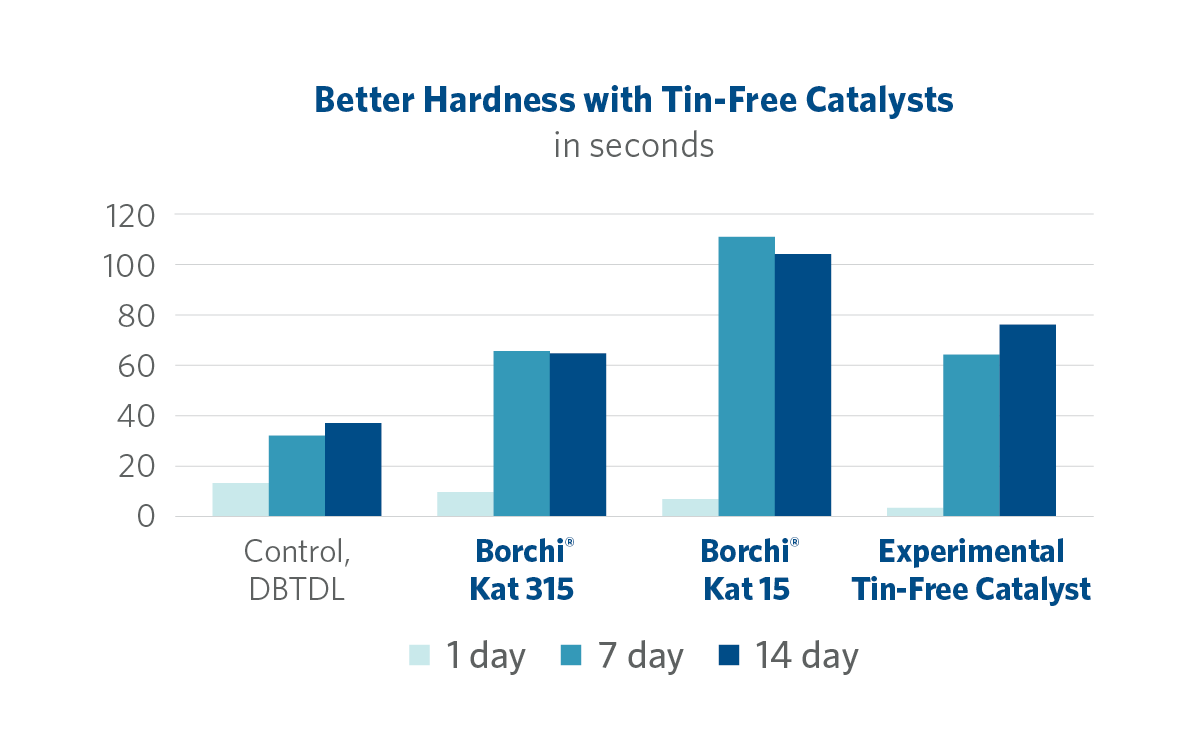

Hardness

A coating’s hardness determines its resistance to factors in the environment that can lead to defects. To measure hardness, our team applied drawdowns on glass plates (150 × 90 × 3 mm) with wet film thickness of 100 microns. They measured König hardness according to ISO 1522 after 14 days.

In a high solids white topcoat for metal, the tin-free catalysts showed better hardness after 7 and 14 days compared to the DBTDL catalyst.

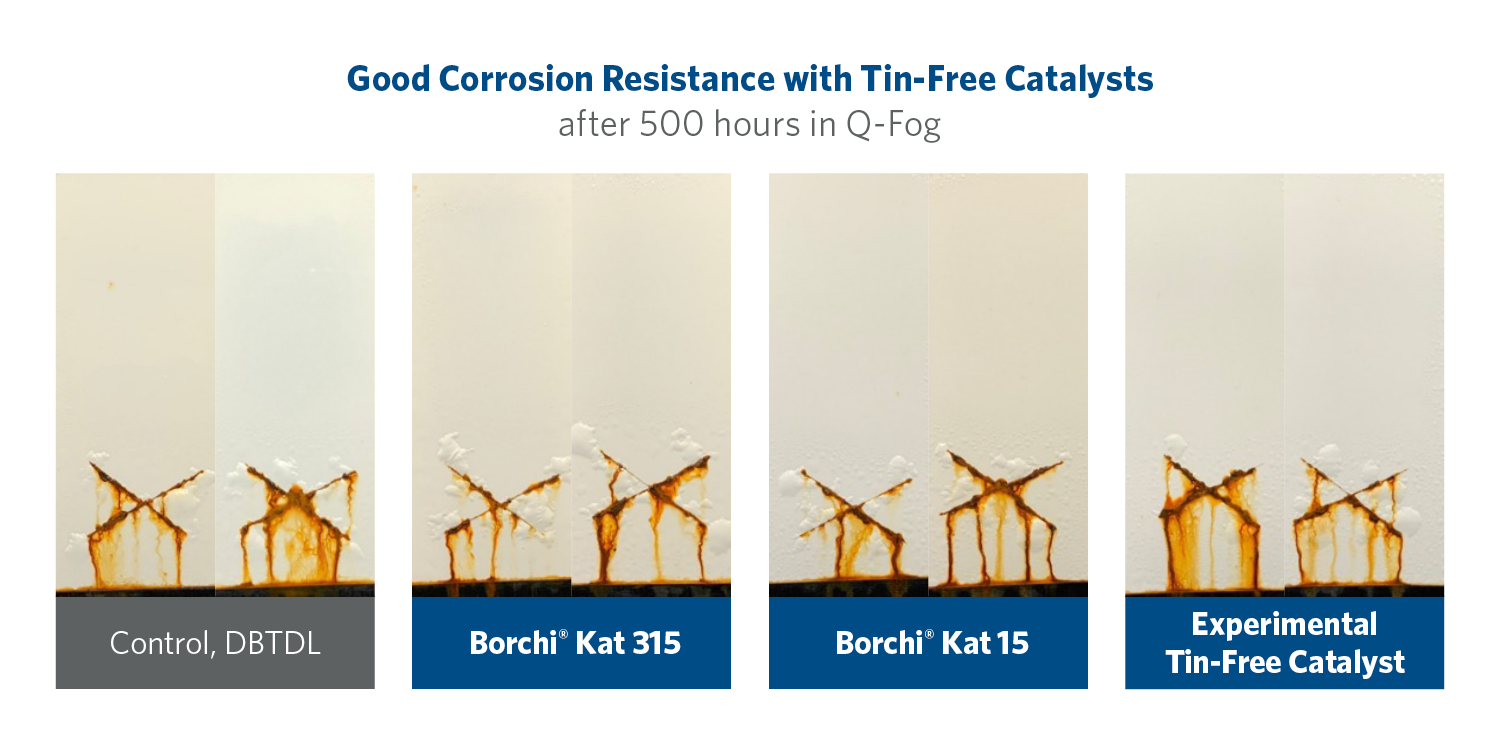

Corrosion Resistance

Unprotected metal exposed to the elements can corrode over time. 2K polyurethane coatings are well known for their excellent protection against corrosion on metal substrates.

To measure corrosion resistance in this case study, our team applied drawdowns on steel panels (Q-Lab, smooth finish, 203 × 101 × 0.5 mm). They masked the edges and rear sides and cross scribed the lower part. They ran a Q-FOG corrosion tester (by Q-Lab) according to ASTM B117 up to 1000 hours.

In a high solids white topcoat for metal, Borchers’ tin-free catalysts provided equal or better corrosion resistance than the DBTDL catalyst.

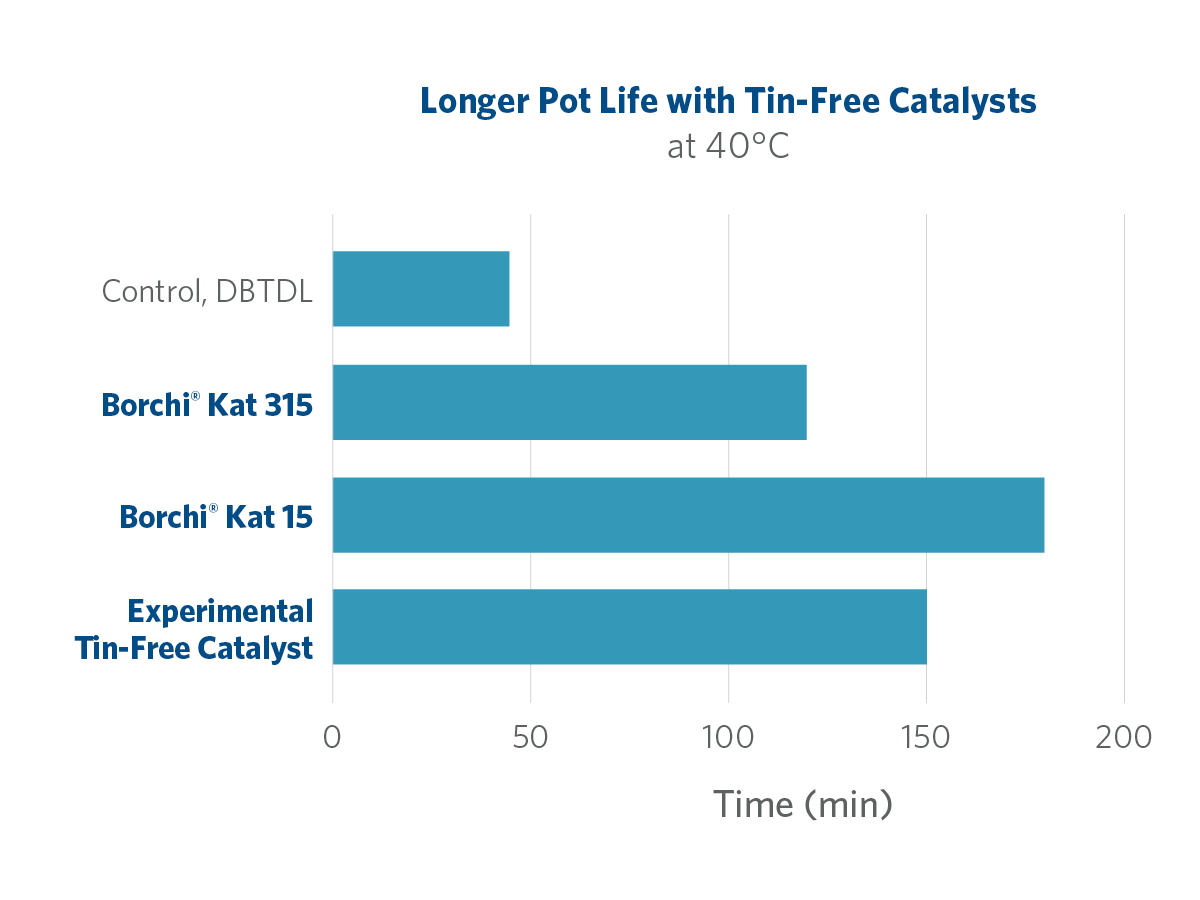

Pot Life

A coating’s pot life is the amount of time in which it can be efficiently applied on to a substrate. In this study, our team measured viscosity periodically at 1000/s using an Anton Paar Rheometer until the initial viscosity doubled. They stored paint samples at 40˚C.

In a white topcoat formulation for airmix and airless application, Borchers’ tin-free catalysts provided longer pot life than the DBTDL catalyst.

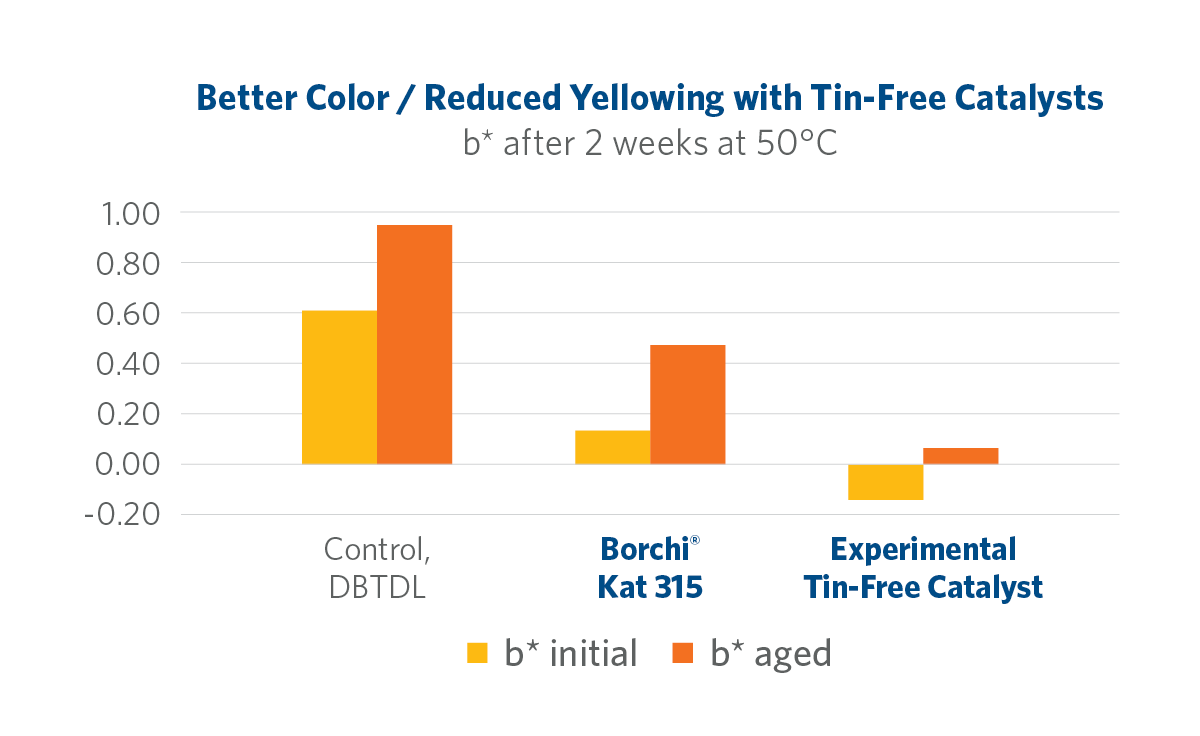

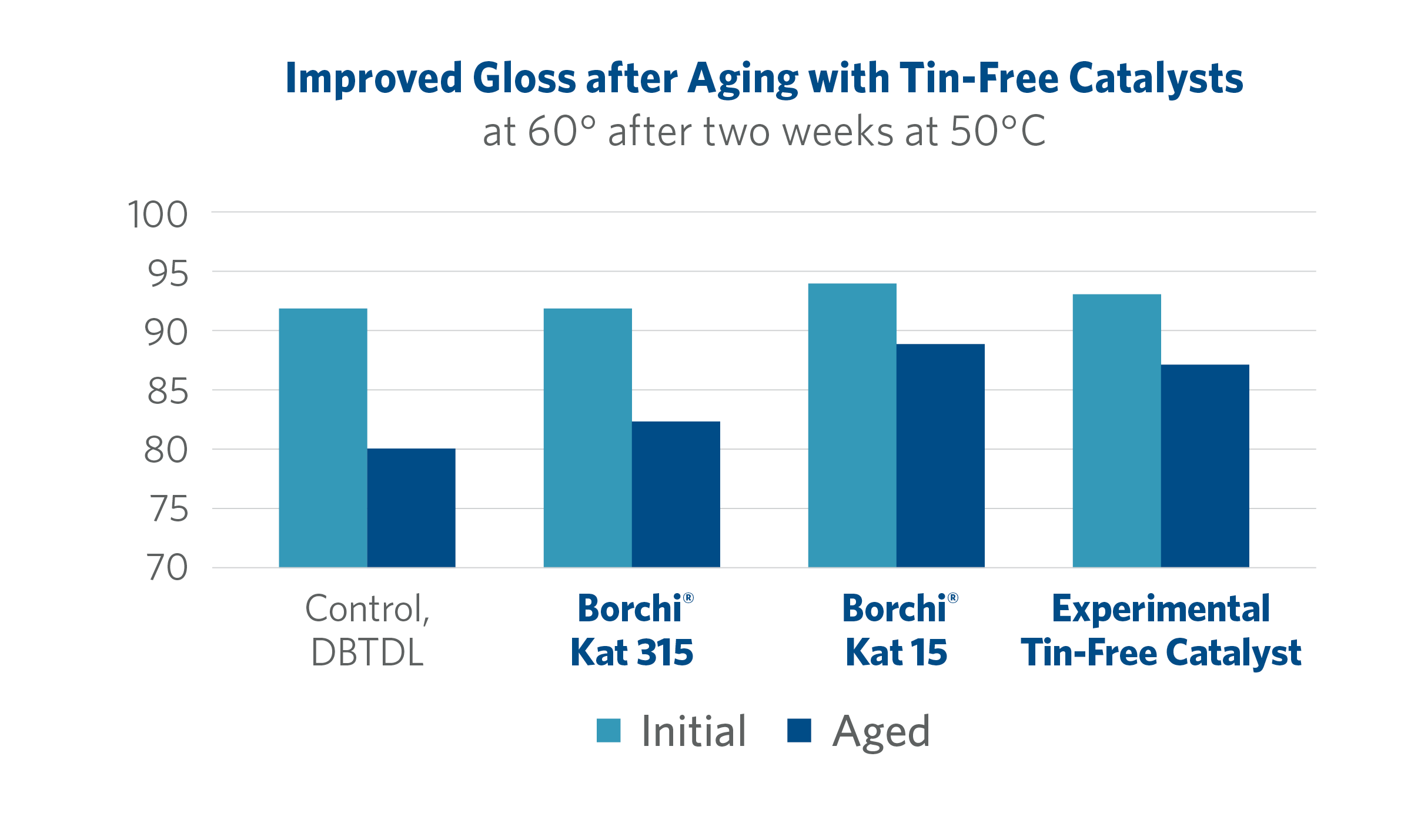

Coating appearance

Catalysts can influence appearance factors like color and gloss in polyurethane coatings. Our experts also examined the impact that tin-free catalysts had on these attributes compared to DBTDL.

Yellowing can occur in polyurethane coatings when exposed to UV light over time as it results in an oxidation reaction.

Borchers’ tin-free catalysts provided lower yellowing in a white topcoat protective and marine formulation compared to the DBTDL catalyst.

Gloss is an important parameter for topcoats coating and can ensure a mirror-like, attractive finish.

In a white topcoat formulation for airmix and airless application, Borchers’ tin-free additives provided high gloss initially and better stability over time compared to DBTDL.

Summary and Conclusion

Tin catalysts have been traditionally favored for their efficiency and reliability. However, their regulatory risks are driving the industry towards safer alternatives.

Tin-free catalysts, such as those based on bismuth, zinc, or zirconium compounds, have emerged as compelling substitutes to replace DBTDL. Compared to tin, they offer reduced toxicity and good performance characteristics.

Milliken & Company has a strong commitment to sustainability. Our goals include providing solutions like tin-free catalysts to help customers create safer products without compromising performance.

Milliken offers various tin-free catalysts under the Borchers: A Milliken Brand product portfolio. These catalysts provide fast drying, strong hardness, resistance to corrosion, long pot life, and great appearance.

Explore our tin-free catalyst offering for more information.