Multi-Functional Dispersing Agent for Water-Based Coatings

Borchi® Gen 1750 is a high molecular weight, VOC-free, polyurethane wetting and dispersing agent that works well with various organic and inorganic pigments and extenders in water-based systems.

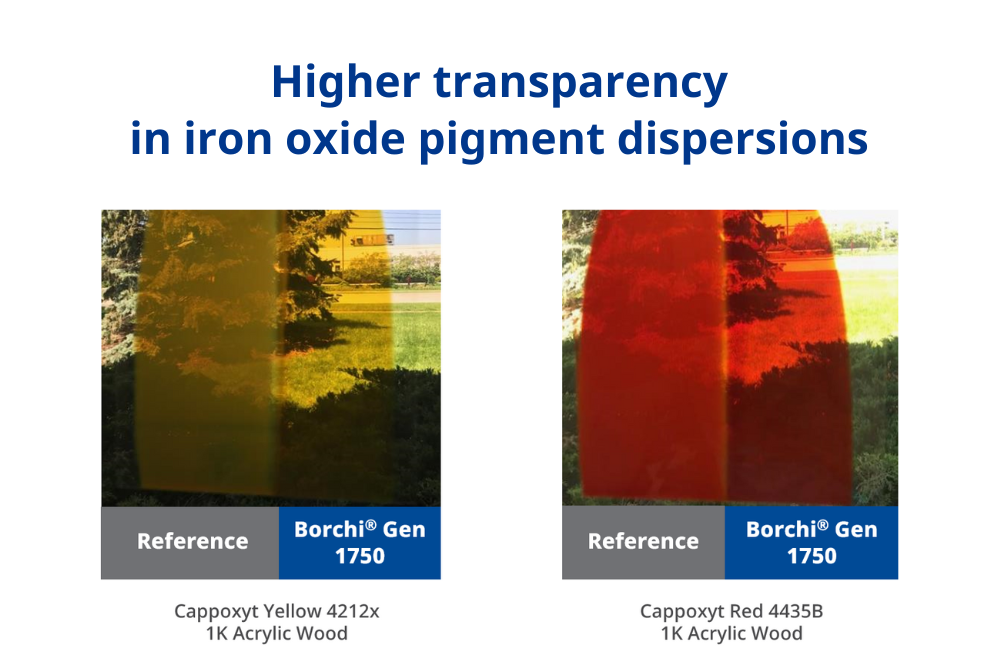

Borchi® Gen 1750 is known for providing excellent dispersions in transparent iron oxide pigments, achieving ultimate transparency for water-based wood and automotive coatings. It can also enable excellent wetting and stabilization of pigments without impacting corrosion protection.

Benefits of Dispersing Agents for Transparent Iron Oxide Pigments

Benefits include low paste viscosity, high pigment loading, shorter grind times compared to industry benchmarks, fast attainment of finer particle sizes, high gloss, and excellent storage stability. Small particle sizes result in high transparency. Low viscosity grinds allow for up to 40 % pigment loading for transparent iron oxide dispersions.

Borchi® Gen 1750 dispersant has been tested in transparent iron oxide red and yellow pigments.

Versatile Dispersant for Use with a Variety of Pigments

Borchi® Gen 1750 can also achieve optimal dispersions with various organic, inorganic, and carbon black pigments.

Reduced Impact on Corrosion Resistance

This dispersant can help with the wetting and stabilization of various pigment blends without impacting corrosion protection.

Applications

Borchi® Gen 1750 is ideal for use in wood, industrial, and automotive coating applications.

Resources

Click here for sales tool on dispersing transparent iron oxide pigments.

Discover more wetting and dispersing agents for various pigments.

Physical Characteristics

Appearance Liquid, yellow Non-volatile content 38 – 42 % pH 3.5 – 5.5 Density 1.03 – 1.07 g/cm3 Viscosity Max. 1000 mPa.s Solvent(s) Water Features

- Efficient for dispersing and stabilizing transparent iron oxide pigments

- Excellent with opaque iron oxides

- Small particle size dispersions producing high transparency

- Low viscosity grinds allowing for up to 40 % pigment loading with transparent iron oxide pigments and over 60 % with opaque iron oxides

- Long-term dispersion stability with no settling is possible when combined with Borchi® Gel PN or NA

- Enables the wetting and stabilization of pigments without impacting corrosion protection

Applications

- Coatings

- Automotive

- Wood

- Industrial

- Coatings

Dosage

The exact dosage should be experimentally determined through a ladder study. Borchi® Gen 1750 should be added to the mill base before adding the pigment. Active pigment loading:

- Transparent iron oxide: 50 – 70 %

- Titanium dioxide: 4 – 8 %

- Inorganic pigments: 5 – 15 %

- Organic pigments: 25 – 70 %

Storage

Protect from the effects of weather and store at temperatures between 5 and 40 °C. Once opened, the container should be resealed immediately after each use. The material will become cloudy over time during storage at temperatures below 10 °C

– this doesn’t affect the performance, but the product should be homogenized before use. The cloudiness can be reversed by heating to room temperature or by heating short term to 40 °C (until clear) without affecting the performance of the product.Safety

Please refer to our safety data sheet for information relating to product safety.

- Availability : All , Americas , Asia , EMEA

- Media : Water-based

- Start Formulations : Air Drying One Component Grey Anti Corrosive Formulation with Bayhydrol UH 2592

Registration :

For chemical inventory status, please review section 15 of the current SDS.

Click here to access the SDS portal.

For additional regulatory information, please contact regulatory@milliken.com.

Wetting and Dispersing Products

Wetting and Dispersing

VIEW DETAILS »Wetting and Dispersing

VIEW DETAILS »Wetting and Dispersing

VIEW DETAILS »Wetting and Dispersing

VIEW DETAILS »