3 Things to Observe in a TiO2 Dispersant for Adhesives

May 1, 2020 | Blog

The adhesives and sealants market is rapidly growing in both the automotive and architectural sectors. The majority of these coatings contain a titanium dioxide (TiO2) pigment for clean color and protection. When these sealants are exposed to the elements, it can be difficult to maintain a bright white color over time. Sealants for windows, doors, siding, and construction materials are constantly exposed to sun and adverse weather conditions, which causes dulling.

TiO2 not only provides a white color, but it also protects sealants from ultraviolet rays and weather damage. This pigment gives adhesives and sealants the strength and durability to preserve color over time. It can even withstand the most intense heat and weather conditions.

But does TiO2 alone provide the best color and protection for your adhesive and sealant formulations?

Inorganic pigments, like TiO2, need more than a solvent or resin to wet and disperse. They require a dispersant for proper separation. Without dispersant additives, pigments tend to agglomerate, creating an undesirable appearance and poor performance characteristics.

When you are choosing a TiO2 dispersant for adhesives and sealants, it is important to ensure compatibility with the pigment, solvents, and resins in the system.

Many formulations in the adhesive market utilize a plasticizer such as diisodecyl phthalate (DIDP) for increased flexibility in the applied sealant. This is used in both the dispersion phase and the final coating formulation. Along with DIDP, these pigment dispersions can contain up to 70% TiO2, additional fillers such as calcium carbonate or talc, a rheological modifier to prevent pigment settling, and a dispersing agent. In these highly filled adhesive systems, testing shows that Borchers’ Borchi® Gen 0650 wetting and dispersing agent is an ideal additive.

Need a sample of Borchi Gen 0650, or a technical data sheet? Click here

Borchers performed pigment dispersion evaluations at 3% active dispersant on 70% pigment loading. Dispersions were screened for the following properties:

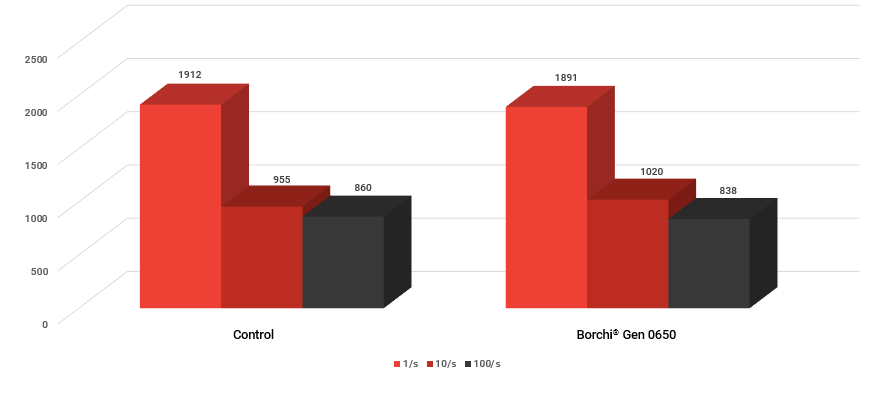

1. Viscosity versus shear rate

Figure 1. shows a commercially available TiO2 dispersion used in the adhesive market. The goal was to maintain the rheological profile of the commercial dispersion. When added into the final formulation, it provides the ideal viscosity for application at high film thicknesses. Borchi Gen 0650 was able to match the commercially available product, making it a viable dispersant additive for TiO2 in adhesives.

Viscosity (cps) 70% TiO2 Dispersions in DIDP

Figure 1: Borchi Gen 0650 gives an identical rheological profile compared to the commercially available dispersion

2. Stability

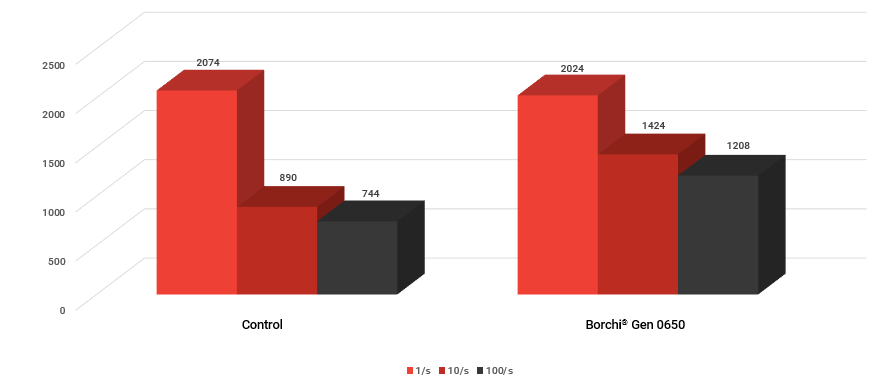

When dispersions are made in production and added later to the final system, it is extremely important to ensure stability over time. This is evaluated by placing the dispersion in a 50°C oven for two weeks. After this time, the dispersion should be evaluated for settling performance and viscosity change.

Figure 2. shows that neither the control nor the Borchi Gen 0650 dispersion showed any signs of syneresis or settling after heat age stability. In the case of the commercially available solution, there was a slight viscosity increase at low shear viscosity (Figure 3).

The same property was observed with the dispersion sample using Borchi Gen 0650. This means that the dispersion made using the Borchers dispersant for TiO2 is stable over time. Thus, there should be no issues upon storage.

Figure 2: Dispersion samples after 2 weeks at 50°C

2 Weeks 50°C Viscosity (cps) 70% TiO2 Dispersion

Figure 3: Borchi Gen 0650 is stable over time

3. Color

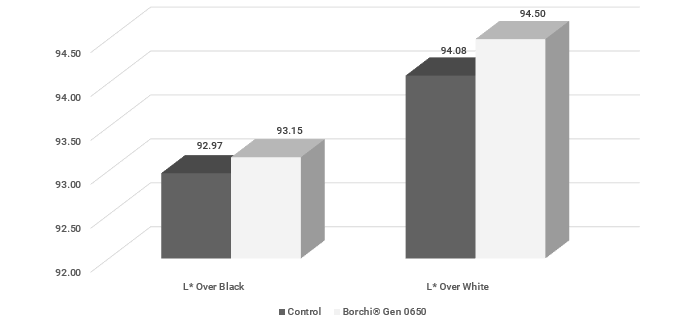

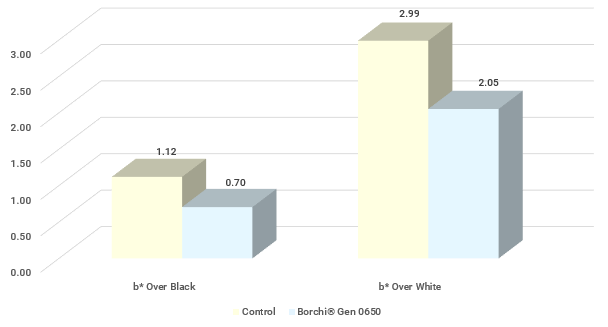

Another important attribute for white adhesive coatings is color values. This was evaluated using an X-Rite MA94 instrument to determine L* a* b* color values. The ideal white coating will have a high L* value and a low b* value. This will produce the brightest, whitest coating, which is extremely desirable in the market.

Figure 4. shows the Borchi Gen 0650 solution maintains a high L* value and is 0.57 units lighter than the competitor. The significant color difference is also seen with the difference in b* value.

Upon storage, the competitive dispersion gives an undertone that is 0.68 units yellower than the Borchi Gen 0650 dispersion (Figure 5). This can be seen in Figure 6, where the low L* value, coupled with the high b* value, makes the coating with the competitive dispersion appear dark and dirty. In comparison, the Borchers additive provides a bright, clean white color.

L* Color Data 20% TiO2 in Adhesive Coating

Figure 4: Borchers dispersion is lighter than control

b* Color Data 20% TiO2 in Adhesive Coating

Figure 5: Control dispersion is yellower than Borchi Gen 0650

Figure 6: Borchi Gen 0650 dispersant gives a brighter, whiter adhesive coating

Borchers’ Borchi Gen 0650 dispersant provides a viscosity profile necessary for ease of incorporation into an adhesive system. It provides a stable viscosity over time and does not settle at high pigment loading levels. This dispersant additive for TiO2 also gives a brighter, whiter color compared to commercially available dispersions. In the case of this evaluation, Borchi Gen 0650 wetting and dispersing additive is an ideal product for a DIDP plasticizer system.

For more information on using a dispersant additive for TiO2 in your adhesive and sealant formulations, please contact cust.service.us@borchers.com (Americas) or cust.service@borchers.com (Europe, Asia, Rest of World)