High-Performance Paint Catalyst for High Solids Alkyd Resins

Borchi® Dragon is a high-performance, organometallic ligand paint catalyst for solvent-based systems containing high solids, long oil alkyd resins. This solution is cobalt-free.

Importance of Low VOCs and Cobalt-Free Driers in High Solids Alkyd Coatings

Regulations are becoming increasingly stringent for coatings around the world.

According to the Cobalt Institute, cobalt toxicity is being questioned by regulatory agencies around the world. For example, the U.S. EPA has prioritized Cobalt and Cobalt Compounds for risk assessment and possible regulatory reclassification. This metal is often used as a paint catalyst and drier.

As Borchi® Dragon is designed to be cobalt-free, this paint catalyst provides performance benefits and can help future-proof against cobalt regulatory scrutiny compared to metal carboxylate alternatives.

VOCs have been a concern for some time in household products such as paint.

Borchi® Dragon Low VOC is a cobalt-free high-performance catalyst option that only contains 2% VOC content (ASTM D2369) for solventborne and solvent-free alkyd formulations.

Benefits of High-Performance Catalysts for High Solids Paints

Borchi® Dragon provides a wide range of performance benefits in paints. These include faster dry times, non-yellowing performance, complexity reduction, and storage stability. This product requires minimum dependency on through driers. Hardness is comparable to cobalt-containing solutions.

Borchi® Dragon works well in both standard and adverse conditions. It extends coatings season windows and prevents wrinkling from over-application in hot weather.

Applications

Borchi® Dragon is ideal for use in architectural, wood, and general industrial end-use applications.

In high solids white enamel architectural coatings, Borchi® Dragon provides brighter whites and enhanced through dry performance compared to cobalt.

Cobalt Containing Borchi® Dragon

Borchi® Dragon provides brighter and cleaner whites compared to cobalt-containing catalysts in high gloss white enamels

Through Dry Time Comparison Under Standard and Adverse Conditions

0.5% Borchi® Dragon provides better through dry times in standard and adverse conditions compared to cobalt-containing and alternative cobalt-free catalysts in high gloss white enamels

When used in clear standard varnish wood finishes, Borchi® Dragon prevents thick film build. It also prevents the coating from turning yellow over time.

Cobalt Containing Borchi® Dragon

Wrinkling from over-application is prevented with the use of Borchi® Dragon

Yellow Value (b*)

Non-yellowing in clear varnishes is enhanced with the use of 1% Borchi® Dragon compared to cobalt-containing catalysts

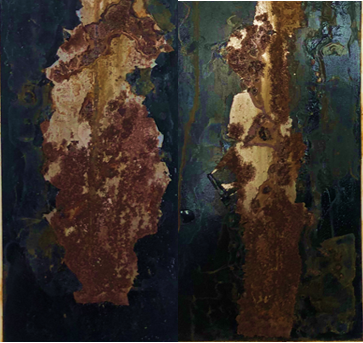

Borchi® Dragon also provides outstanding wet adhesion, corrosion resistance, and dry times in high gloss black direct-to-metal (DTM) industrial coatings.

Cobalt Containing Borchi® Dragon

Borchi® Dragon provides better wet adhesion than cobalt containing catalysts in high gloss black DTM coatings

Cobalt Containing Borchi® Dragon

300 hours NSS

Borchi® Dragon provides better scribe creep and

reduced delamination compared to cobalt-containing catalysts

Additional Solutions

Borchi® Dragon is great for use with Borchi® Shield MEKO-free anti-skinning agent for skin prevention in high solids and long oil coating systems with reduced VOCs.

Resources

Starting Point Formulations

Interior & Exterior High Gloss Paint Formulations with Urakyd AD 130

Cobalt- and MEKO-free High Solid Decorative Paint Formulation with Urakyd HS233

Cobalt- and Oxime-free Interior and Exterior High Gloss Decorative Formulation with Vilkyd 212LA70

Physical Characteristics

Appearance Brown to amber liquid Viscosity Max. 100 mPa·s (informative) ISO 3219 (A) (20 °C) Density Approx. 0.88 g/cm3 (informative) ISO

2811-2 (20 °C)Features

- Faster drying times particularly in long oil alkyds

- Allows for <350g/L alkyd formulation with higher oil content

- Fast drying in adverse ambient conditions down to 40°F (4.4 °C)

- Reduction in complexity of drier package in formulation

- No yellowing and brighter whites when compared to cobalt driers

- Provides wrinkle-free appearance when utilized with thick film applications

- Allows for low VOCs in coatings with high solids alkyd resins

- Cobalt-free drier

Applications

- Coatings

- Wood

- Industrial

- Protective and Marine

- Architectural

- Automotive

Dosage

All resin systems are unique and will require the level of Borchi® Dragon to be optimized for the best cost and dry performance. We recommend using a ladder study starting at 0.5 % up to 3 % of Borchi® Dragon as supplied on resin solids. Optimized dosage must be determined as excessive Borchi® Dragon could reverse dry performance. Borchi® Dragon should be added as one of the last ingredients before the Anti-Skinning agent.

Storage

Protect from the effects of weathering and store at temperatures between 5 and 30 °C. Color of product varies on storage.

Safety

Please refer to our safety data sheet for information relating to product safety.

Formulation Guide

- Availability : Americas , Asia , EMEA

- Media : Solvent-based

Registration :

For chemical inventory status, please review section 15 of the current SDS.

Click here to access the SDS portal.

For additional regulatory information, please contact regulatory@milliken.com.

High-Performance Catalysts Products

High-Performance Catalysts

VIEW DETAILS »High-Performance Catalysts

VIEW DETAILS »High-Performance Catalysts

VIEW DETAILS »High-Performance Catalysts

VIEW DETAILS »